The Technology

Bulk metallic glass (BMG) is a revolutionary material. It has an amorphous structure which gives it a variety of unique features.

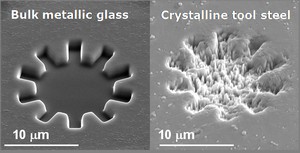

- It can be patterned on the nano-scale with an atomically smooth surface finish due to its lack of crystal grain structures

- It has much higher strength and hardness than a comparable crystalline metallic alloy

- It has a glass transition temperature above which it flows like a glass. This allows stress free complex shapes to be imprinted in the material using simple thermoforming techniqes

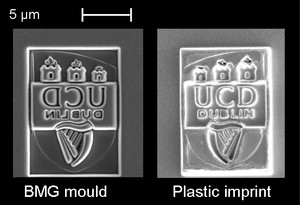

Tetra Materials produces, processes and patterns metallic glass alloys to provide low cost, highly durable, nano-featured moulds. These moulds can be used to manufacture low unit cost microfluidic chips in a wide variety of polymers. The accuracy of BMG tooling in transferring arbitrarily complex patterns into plastics a sub-micron level is shown below.

The excellent mechanical properties of metallic glass make it an ideal tool material for high volume moulding, while the combination of no crystal structure along with a glass transition temperature allow robust nano-features to be imprinted on the material with a low cost, quick and simple process. The resulting moulds are robust and stress free. This is a significant advantage that BMG thermoformed moulds have over the conventionally elecro-formed moulds used for micro-moulding. The electro-deposition process, as well as being slow and expensive, often generates large internal stresses in the mould. This make them more fragile and limits the operating pressures that can be used on the tool.